Best Price on Dedusted Wipers - Lint Free M 3 Wipes – Bei Te

Best Price on Dedusted Wipers - Lint Free M 3 Wipes – Bei Te Detail:

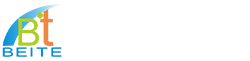

The surface of the product has a hole-like structure, which is mostly used for wiping the surface of precision objects; low dust, good wiping effect, high water storage capacity, soft and pure. Chemical agents such as acid and alkali resistance. Low dust and anti-static, can effectively control the amount of static electricity generated. Can be used multiple times. it is a widely used in the electronics industry. It can also be used as a universal wipe for daily cleaning.

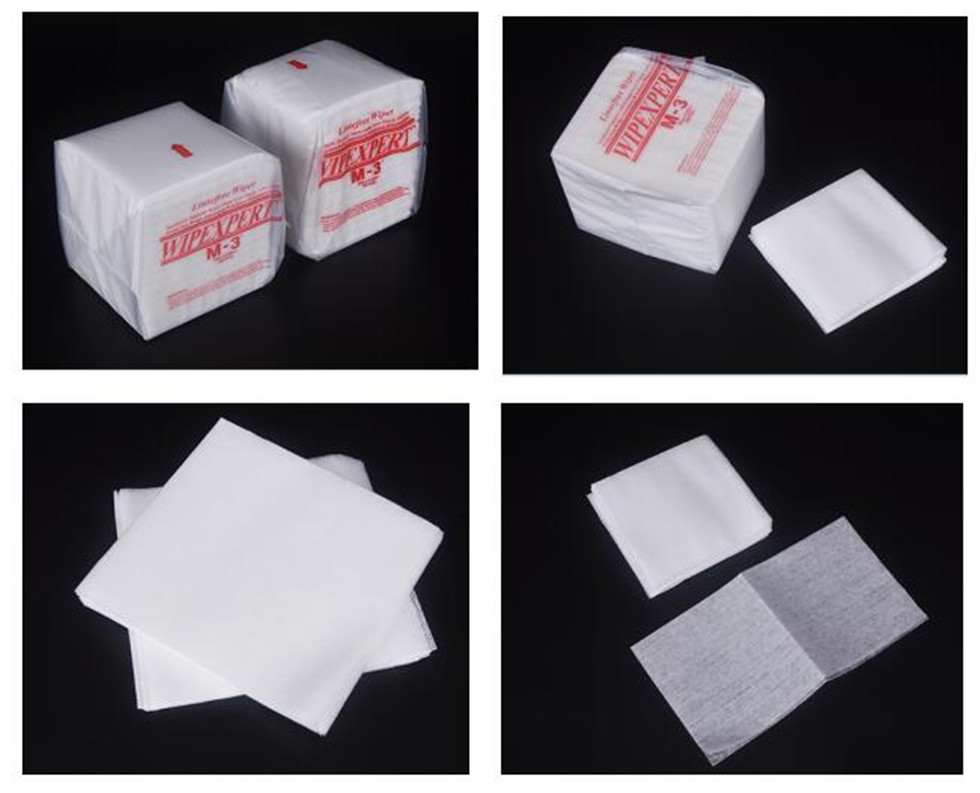

Suitable for indicating controllers, integrated circuits, liquid crystal displays, printed circuit boards, resistors, capacitors, coils, optical electronic components, ceramic crystals, light-emitting diodes, micro-batteries, magnetic disks, magnetic tapes, magnetic heads, assembly components, cores, automobiles, etc.

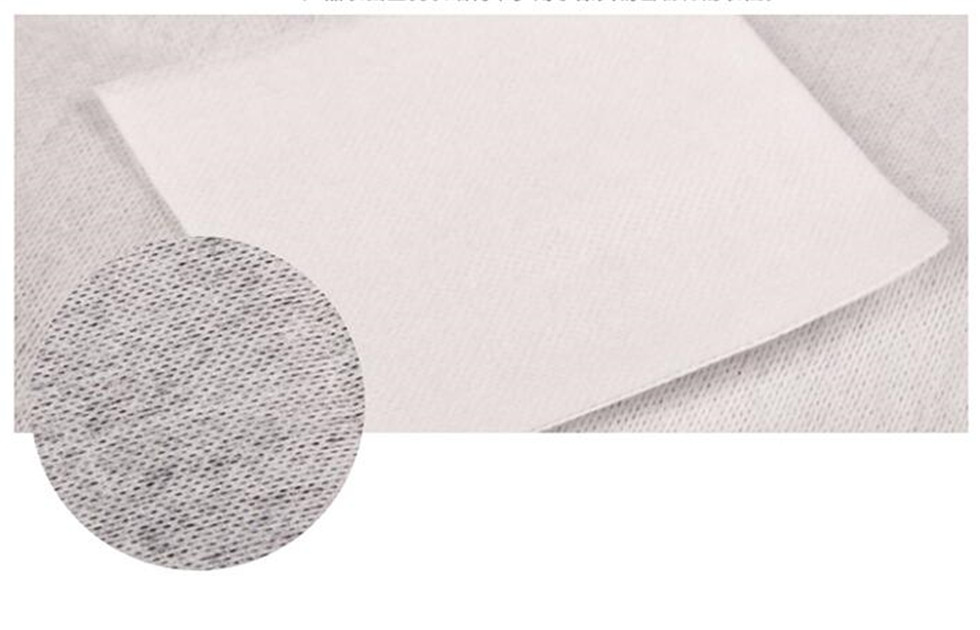

The M-3 Clean Wiper is an entangled non-woven fabric with a 100% filament rayon composition. Because rayon is completely cellulosic, this is an extremely absorbent clean wiper. The wiper is a 25*25 cm, quarter-folded which is sized to fit the hand. This wipe is used extensively in the compact disk and magnetic tape industries.

|

Product Name |

M-3 Cleanroom Cleaning Wiper |

|

Materials |

100% viscose or 70% Viscose+30% Polyester |

|

Basic Weight |

40 gsm |

|

Product Size |

25cm X25cm,1/4 folded |

Features:

1, 1/4 fold;

2, It is convenient to use, with properties of cleanness, no debris, a strong strength and high absorption.

3, Low lint release. It adopted the latest technology from 100% viscose or 70% Viscose+30% Polyester.

4, It is widely used to remove liquid and oil on the circuit board surface, in electronic industries, with high absorption, no-easy fluffing, strong tensile strength on both vertical and horizontal aspects, excellent wet strength and suitable for a variety of solvents.

5, Heat-resistant

6, Both dry and wet environment

7, It must be your best choice for removing dust and oil.

Applications:

1, Wiping in ISO Class 6(1000) cleanroom.

2, Maintaining the equipment in the cleanroom.

3, Consoling and absorbing the water and solvent in the cheanroom.

4, Bio-pharmacy,automatic instruments,computer accessory manufacturing.

5, Optic and lens manufacturing,encapsulation and testing.

Product detail pictures:

Related Product Guide:

With sophisticated technologies and facilities, strict top quality handle, reasonable value, exceptional support and close co-operation with clients, we are devoted to furnishing the ideal worth for our clients for Best Price on Dedusted Wipers - Lint Free M 3 Wipes – Bei Te , The product will supply to all over the world, such as: Botswana, Atlanta, Brazil, Please feel cost-free to send us your specifications and we'll respond to you asap. We've got a professional engineering team to serve for the every single detailed needs. Free samples may be sent for you personally to know far more facts. So that you can meet your desires, please really feel cost-free to contact us. You could send us emails and call us straight. Additionally, we welcome visits to our factory from all over the world for much better recognizing of our corporation. nd merchandise. In our trade with merchants of several countries, we often adhere to the principle of equality and mutual advantage. It is our hope to market, by joint efforts, both trade and friendship to our mutual benefit. We look forward to getting your inquiries.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.