Hot sale Equipment Packaging Bag - Wafer paper lint-free wafer paper – Bei Te

Hot sale Equipment Packaging Bag - Wafer paper lint-free wafer paper – Bei Te Detail:

Wafer paper is also called anti-static accumulation paper, silicon wafer paper, buffer pad in semiconductor wafer box, solar wafer buffer pad, pad in semiconductor wafer box, PCB buffer, conductive spacer, anti-static wafer spacer, conductive wafer spacer, circular wafer spacer and wafer square, and is also called anti-static embossed wafer pad according to its surface treatment process. This product is made of permanent conductive or antistatic film material by hot pressing, embossing and die cutting. The paper surface can be made smooth, and various patterns can be made according to requirements. The product can be made into any size and shape according to the requirements, and the finished product has excellent dimensional stability, clean appearance, no powder or dust. The embossed patterned wafer pad can not only effectively prevent the product from being damaged by static electricity, but also play a certain buffering role. These products are widely used in the packaging of TFT-LCD, solar cells, wafers, solar silicon wafers and multi-monocrystalline silicon wafers in chip manufacturing and packaging enterprises.

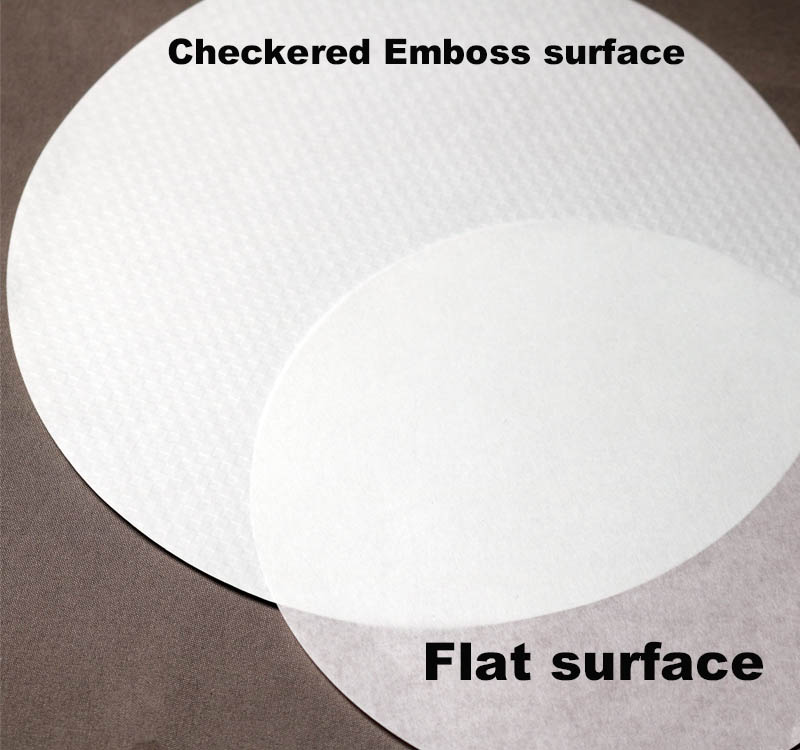

Process: The surface can be calendered or embossed, and the embossed pattern height is 20μm, which plays a better role in spacing and buffering without increasing the thickness.

Cleanliness: class 1000

Surface resistance: 103-1011Ω

Packing: PP vacuum bag

| Lint-free wafer spacer BT silicone wafer paper | |||||

| No | name of an article | model | Size | material | package |

| 1 | 4 “lint-free wafer spacer | BT-100-01-04 | R=100MM, H=0.08MM | Pure wood pulp | 200 pcs/Bag |

| 2 | 5 “lint-free wafer spacer | BT-125-01-05 | R=125MM, H=0.08MM | Pure wood pulp | 200 pcs/Bag |

| 3 | 6 “lint-free wafer spacer | BT-150-01-06 | R=150MM, H=0.08MM | Pure wood pulp | 200 pcs/Bag |

| 4 | 8 “lint-free wafer spacer | BT-200-01-08 | R=200MM, H=0.08MM | Pure wood pulp | 50 pcs/Bag |

| 5 | 12 “lint-free wafer spacer | BT-300-01-12 | R=300MM, H=0.08MM | Pure wood pulp | 50 pcs/Bag |

| 6 | 4 “embossed lint-free wafer spacer | BT-100-02-04 | R=100MM, H=0.16MM | Pure wood pulp | 200 pcs/Bag |

| 7 | 5 “embossed lint-free wafer spacer | BT-125-02-05 | R=125MM, H=0.16MM | Pure wood pulp | 200 pcs/Bag |

| 8 | 6 “embossed lint-free wafer spacer | BT-150-02-06 | R=150MM, H=0.16MM | Pure wood pulp | 200 pcs/Bag |

| 9 | 8 “embossed lint-free wafer spacer | BT-200-02-08 | R=200MM, H=0.16MM | Pure wood pulp | 50 pcs/Bag |

| 10 | 12 “embossed lint-free wafer spacer | BT-300-02-12 | R=300MM, H=0.16MM | Pure wood pulp | 50 pcs/Bag |

I. performance:

1, good protection ability:

1), superior chemical resistance, chemically inert to most acids, alkalis.

2) Good liquid proof function.

3) Excellent bacteria proof effect, puncture resistance and low fuzziness: it is composed of continuous filaments and its surface is smooth, so it is not easy to fuzzing. In addition, it has excellent bacteria-proof effect, so it can be widely used in the packaging of sterile medical products and can prevent mites from breeding.

2. High strength and excellent dimensional stability:

1), because it does not absorb water, so there is no change in dry and wet strength.

2) The size does not change with humidity basically, and the change of sheet size is less than 0.01% under constant temperature and relative humidity in the range of 0-100%.

3. Excellent flexibility: it easily exceeds 20,000 deflections.

Product detail pictures:

Related Product Guide:

Our enterprise since its inception, constantly regards product good quality as organization life, constantly improve production technology, strengthen merchandise high quality and continuously strengthen enterprise total good quality administration, in strict accordance with all the national standard ISO 9001:2000 for Hot sale Equipment Packaging Bag - Wafer paper lint-free wafer paper – Bei Te , The product will supply to all over the world, such as: Somalia, Denver, Malaysia, We have advanced production technology, and pursuit innovative in products. At the same time, the good service has enhanced the good reputation. We believe that as long as you understand our product, you must be willing to become partners with us. Looking forward to your inquiry.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.