Manufacturing Companies for Printed Silicone Paper - Anti rust VCI paper – Bei Te

Manufacturing Companies for Printed Silicone Paper - Anti rust VCI paper – Bei Te Detail:

VCI antirust paper introduce:

What is vapor phase rust prevention?

First understand what rust is.

Rust is a process in which metal wants to restore its stable oxide state, that is its original mineral form. The greater the energy consumed in refining a specific mineral into a metal, the faster the corrosion rate of the metal. Corrosion is an electrochemical change process. A small amount of electrical ions exist on the untreated metal surface, and these particles will move from the high energy area (anode) to the low energy area (cathode), thus generating current, which is called corrosion.

Vapor phase antirust paper is refined by special process. In the confined space , VCI contained in the paper begins to sublimate and volatilize the antirust gas factor at normal temperature and pressure, which diffuses and permeates to the surface of the antirust object and adsorbs it to form a dense protective film layer with single molecule thickness, thus achieving the purpose of antirust.

Features of vapor-phase antirust paper

1. Oil-free packaging, no smearing, degreasing and cleaning procedures, saving labor cost and time.

2. High-performance VCI is uniformly contained in antirust paper, which can quickly exert antirust effect after packaging.

3. Effective rust prevention can be realized even without direct contact with metal, especially for metal pieces with complex appearance.

4. It has dual functions of rust prevention and packaging.

5. Compared with vacuum packaging, it has low cost and simple to use.

6. Clean, harmless, nontoxic, environmentally friendly and safe.

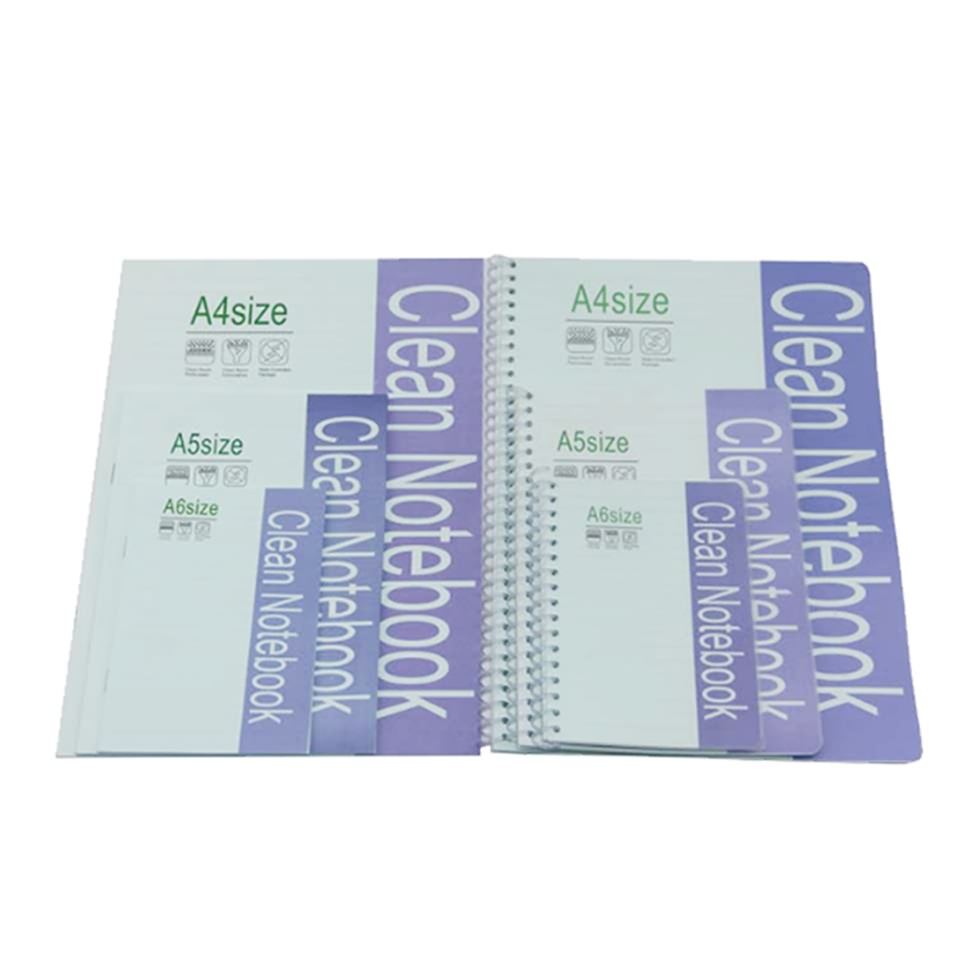

Applicable metals:

iron metal, alloy steel, cast iron, copper, brass, bronze, electroplated metal, zinc and alloy, chromium and alloy, cadmium and alloy, nickel and alloy, tin and alloy, aluminum and alloy and other metal materials and products.

Precautions for use:

1. The antirust paper should be in close contact with the surface of the antirust object , and there should be no obstacle between them.

2. Before packaging, the surface of the antirust object should be clean, dry and free of foreign particle.

3.If the surface of the antirust object is regular, the method of full coverage can be

4. Wear clean gloves when packing, and do not touch the antirust items with bare hands.

5. It does not contain nitric acid, phosphoric acid, chromic acid, silicon and other heavy metals, and is safe and pollution-free.

Rust prevention period:

1 ~ 3 years (use according to requirements and specifications)

Storage and storage: Sealed packaging, stored in a cool, dry place, avoid direct sunlight, avoid contact with fire sources and corrosive substances. The shelf life is 12 months from the date of delivery.

Manufacturing process:

The virgin pulp is made of unbleached kraft wood pulp, beaten, sizing, filling (material), copied on the paper machine, and then coated with rust remover (such as sodium benzoate, sodium benzoate and sodium nitrite mixture) on the base paper by dipping, brushing or glue coating, and then dried.

Anti rust paper has high toughness and folding resistance, but also does not contain any material that may cause metal rust. Used for ferrous metal packing of cast iron, steel, galvanized metal products, and multi-color metal packing of copper and copper alloy products. If one side of the base paper is coated with paraffin wax or polyethylene resin, and the other side is coated with vapor phase antirust inhibitor, vapor phase antirust paper can be made.

Difference between vapor phase antirust technology and traditional antirust technology;

Due to the influence of weather, geographical location, product materials and other factors, many workpieces will have rust on their surfaces. When choosing anti-rust products, many friends don’t know how to choose vapor-phase anti-rust paper and traditional anti-rust paper, so let’s introduce the difference between vapor-phase anti-rust paper and traditional anti-rust paper.

Vapor phase anti-rust paper is a special anti-rust packaging material, which is based on special neutral paper, coated with different special substances-VCI, and after a series of post-processing. Among many materials in packaging industry, vapor-phase antirust paper is a kind of high-tech product, and its core technology is embodied in VCI. VCI technology is a comprehensive technology integrating organic synthesis, physical chemistry, corrosion and protection, metal materials, paper processing and polymer technology. Different VCI systems have great differences in safety, high efficiency, environmental protection and applicability, so they are embodied as products with various forms and functions.

Traditional anti-rust paper is contact type anti-rust paper or slightly vapor-phase anti-rust paper with solely single corrosion inhibitor component. The index, surface state, physical properties and anti-rust effect of traditional anti-rust paper are not very good. However, the current vapor-phase antirust paper, with high efficiency and low vapor-phase corrosion inhibitor, has vapor-phase antirust and contact antirust properties, with good effect, and can achieve various structural forms to meet different packaging strength requirements.

Compared with traditional antirust paper, the advantages of vapor-phase antirust paper are as follows:

1. It can effectively prevent metal from moisture.

2. The anti rust period is 1-2 years.

3. It can be reused and biodegradable.

4. Non toxic and harmless.

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. High-quality is our life. Purchaser need is our God for Manufacturing Companies for Printed Silicone Paper - Anti rust VCI paper – Bei Te , The product will supply to all over the world, such as: kazakhstan, Suriname, Romania, Based on products with high quality, competitive price, and our full range service, we have accumulated professional strength and experience, and we have built up a very good reputation in the field. Along with the continuous development, we commit ourselves not only to the Chinese domestic business but also the international market. May you moved by our high quality products and passionate service. Let's open a new chapter of mutual benefit and double win.

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.