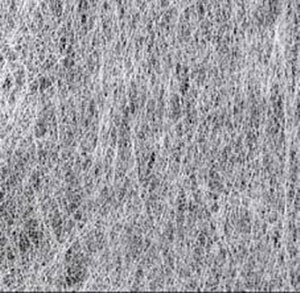

The basic raw materials of paper, textiles and nonwovens are usually cellulose fibers. The difference between the three products lies in how the fibers are combined.

Textiles, in which the fibers are held together mainly by mechanical entanglement (e.g. weaving).

Paper, in which cellulose fibers are basically bonded together by weak chemical hydrogen bonds.

-In contrast, nonwovens are bonded together in one or more of the following ways:

-Strong chemical bonding agent. For example, synthetic resin, latex or solvent.

Melting adjacent fibers (thermal bonding).

-Random mechanical entanglement of filaments. For example: spinning lace bonding (i.e. hydroentanglement), needle punching or stitch bonding.

The form of finished non-woven fabric products is as follows:

-covering. E.g. for diapers.

-Geotextiles (geosynthetics). For example, to consolidate inclined earth embankment or to drain water in civil engineering.

-Construction paper. For example: wooden frame roof, breathable paper (used for building walls), floor covering.

-Tyvek products. E.g., floppy disk bracket, envelope.

-other goods. For example: wet wipes; Napkin; Tableware; Tea bag; Clothing lining; Medical treatment (e.g. surgical gown, mask, hat, shoe cover, wound dressing); Filters (automobiles, ventilation equipment, etc.); Battery separator; Carpet backing; Oil absorbent.

Although non-woven fabrics are generally regarded as disposable articles, in fact, a considerable part of them are durable articles.

How to use nonwovens?

Besides simple definitions, these engineered fabrics also open up a new world for all types of industries.

Nonwoven materials can be disposable fabrics with limited life or very durable fabrics. Nonwoven fabrics have specific functions, such as absorbency, liquid repellency, resilience, stretchability, softness, strength, flame retardancy, washability, cushioning, filterability, bacterial barrier and sterility. These characteristics are usually combined to create a fabric suitable for a specific job, while achieving a good balance between product life and cost. They can imitate the appearance, texture and strength of fabrics, and can be as big as the thickest filler.

The following are some properties that can be obtained by using nonwovens:

Water absorption, bacterial barrier, cushioning, flame retardancy, liquid repellency, elasticity, softness, strength extension and washability.

Nowadays, the innovation of nonwovens is growing rapidly with the increasing demand for them, which almost provides unlimited possibilities for various industries, including:

Agriculture, covering, clothing lining, automobile roof, automobile interior, carpet, civil engineering, fabrics, disposable diapers, envelopes, household and personal wet wipes for house packaging, sanitary products, insulation labels, laundry products, sterile medical products.

Beite dust-free wiping paper

Post time: Nov-15-2021