ESD Cleanroom wiper

Specifications:

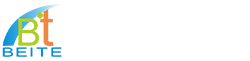

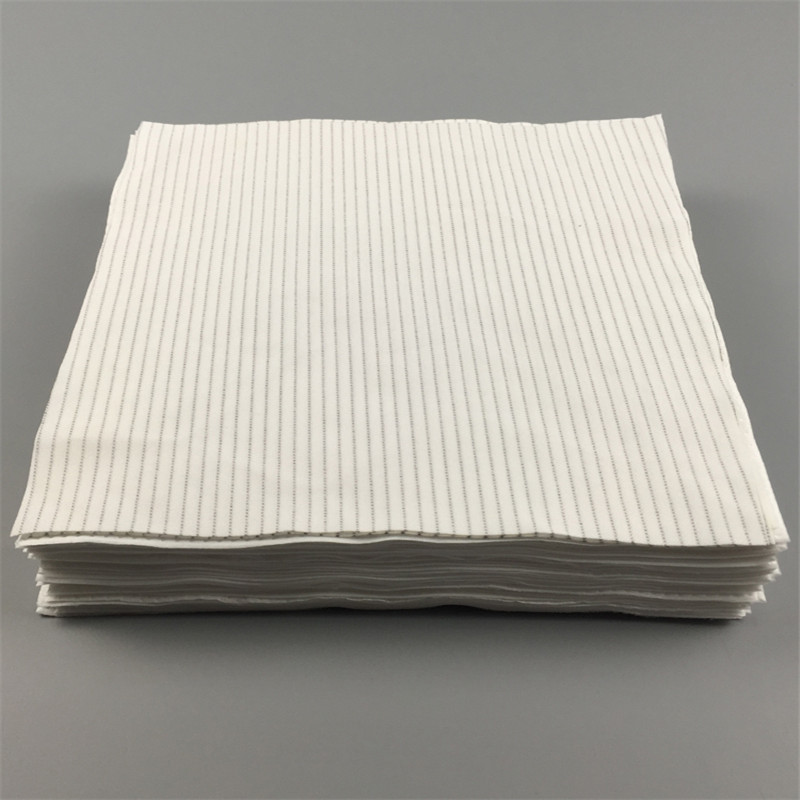

Our ESD wipes are manufactured from antistatic polyester and carbon core nylon materials in a unique, no-run knit construction. Extremely low in particle generation and extractable chemicals, select wipers are specially processed and packaged in Class 100/ISO 5 cleanrooms for optimum cleanliness and material purity.

1. It's convenient to use, with properties of cleanness, no debris, a strong stretch strength and high absorption.

2. It's widely used to remove liquid and oil on the circuit board surface, in electronic industries,with high absorption, no-easy fluffing, strong tensile strength on both vertical and horizontal aspects, excellent strength and suitable for a variety of solvents.

3.It is ideal in eliminating traces of contaminants in critical environments in the fields of microelectronics, micro-mechanics, and pharmaceutical etc. It is an effective cleaning tool in the Cleanroom.

| Material | 100% Polyester and carbon fiber |

| Weight | 120gsm+/-5gsm |

| Color | White |

| Package | 150pcs/bag,10bags/ctn |

| Size | 4''x4'',6''x6'', 9''x9'', or customer size |

| Class | 100-1000 |

| Edge | Laser cut or Ultrasonic cut |

| Certificate | SGS Rosh |

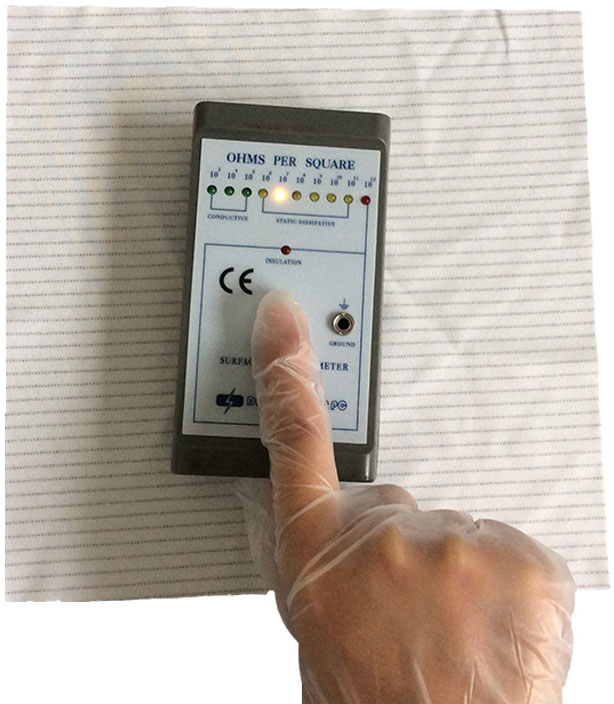

| Surface resistance | 10E6-10E9 ohms |

| Product Keywords | ESD Anti-static Wipers/ ESD Cleanroom Wipers/lint free ESD Microfiber cleanroom wiper |

Features:

1. Excellent absorbency, no detergent needed

2. Low particles. Each wipe is effective both as a dry wipe and in conjunction with our cleaning Chemistry.

3. Excellent wetting characteristics

4. Ideal for cleaning machines used in SMT processes

5. Static dissipative ESD wiper for all Electronic manufacturing and optical cleaning process.

Technical Data Sheet:

|

Item |

Result |

|

Basis Weight (+/-5 %) |

125 g/m2 |

|

Thickness (+/-0.05mm) |

0.30 mm |

|

Liquid Absorption Rate |

<3 seconds |

|

Sealing |

Ultrasonic Seal Edge |

Application

For clean room with class 100~1000.

Widely used in IC assembling and testing, mobile phone and disk manufacturing.

Optical and biotechnology products

Customer designed size is available.

Application: Semiconductor production line, Chips, Semiconductor assembling Line, Disk drive, Composite materials, LCD display product, SMT Production Line, Precision Instruments, Clean room and Production line, etc

Used in circuit board production line,medical device,camera lens, optics and automobiles

Designed for cleaning medical equipment, tools in laboratory, glass, delicate surfaces and general cleaning