Silicone Cleaning Roller

The silicone roller is a self-adhesive dust removal product made of the reaction of silicone and key raw materials. The surface is smooth like a mirror, the volume is light, and the particle size is less than 2um. The product can effectively adhere impurities such as hair, dander and dust, and can easily transfer the impurities to the sticky paper. Thus, the self-adhesiveness of silica gel can be guaranteed for a long time. There are multiple viscosity options. A variety of handles are available, high elasticity, good electronic performance, moisture-proof, moisture-proof and friction-resistant, non-toxic, rust-free and pollution-free.

1. The formula ensures that the product is highly viscous and durable, not easy to age, and does not fall off chips.

2. Feel comfortable when using, and the wheel can rotate freely.

3. It can remove tiny pollutants, and can be used in conjunction with sticky paper.

4. Widely used in industries such as circuit boards, display screens, printing, clea

Product Name: Silicone Cleaning Roller

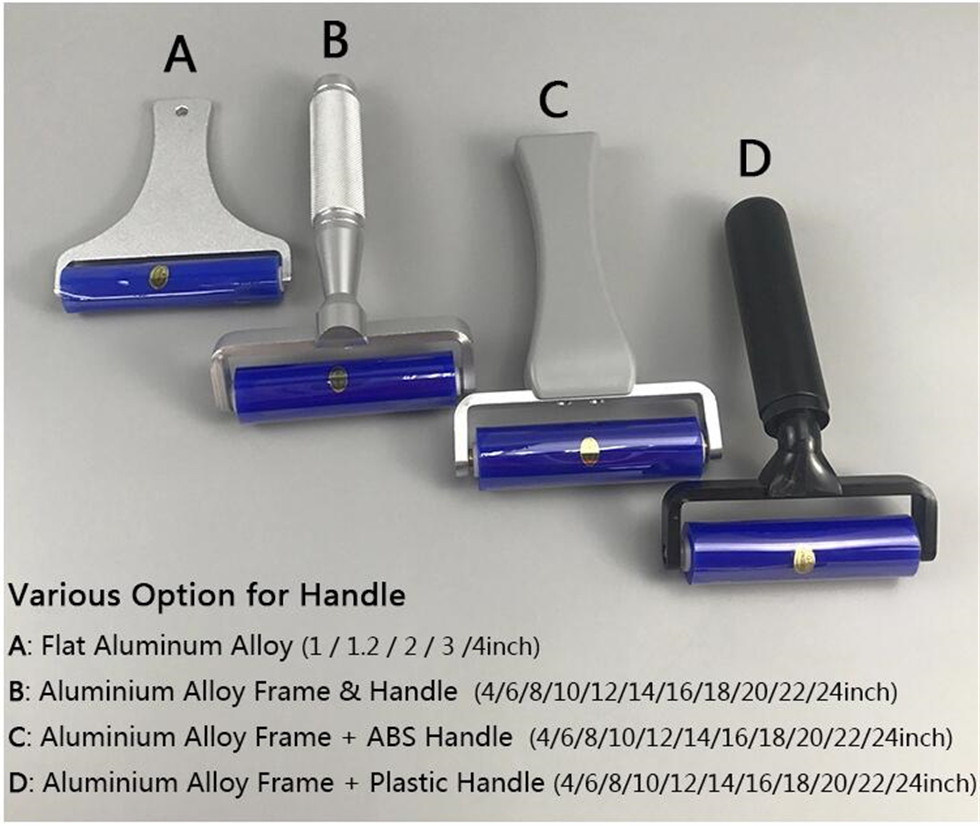

Material :Silicone roller + metal bracket or plastic bracket + metal handle or rubber handle

Size:4 inch、6 inch、8 inch、10 inch、12 inch、14 inch、16 inch,more sizes can be customized.

Tackiness: super high/high/middle/low/no tackiness

Diameter:32mm,28mm

Features:

There are three different tackiness:high/middle/low.

The silicone cleaning roller can remove the small particles,impurities,fibers,copper shavings,dust and etc. which generated during the production process of the electronic products to reduce the defective rate of the finished products.

Long life time worked with the DCR pad.

Diameter of the silicone roller can be customized.

Applications:

Circuit Board Manufacturing

PCB Assembling

LCD liquid crystal display

Light Guide Film Manufacturing

Film Printing

SMT

Electrical light conductor and etc

How to use & Warm tips

1. Use the backward rolling method.(Especially the uneven cleaning products, such as PCB board).

2. Cleaning silicone: Please use anhydrous alcohol wipe, then dry by air gun.

3. Can't connect to benzene and ester solvents (such as Toluene, screen washing agent, acetyl tributyl citrate, ethyl acetate, etc.) Once contact, immediately wipe quickly with absolute alcohol, dry by air gun.

4. Each Silicone roller can be used for 5000 times, if the stickiness is degressive, please clean it by anhydrous alcohol and bake it for 30 minutes in the oven at 50 °C temperature. Stickiness will be renewed.

5. Please do not use silicone wheel to cleaning floors, walls and rough board

6. Please not use sharp blade scratch silicone.