Polyester cleanroom wiper

1009 is an all-purpose wipe made from 100% continuous-filament polyester in a double knit, no-run, interlocked pattern. Soft and non abrasive, they are ideal for critical environments where contamination control is essential.

| Product | cleanroom wiper 1009DLE、1009SLE |

| Material | 100% polyester |

| Product Model | 1009DLE/1009SLE |

| Weight | 110, 120, 140gsm available |

| Size(inch) | 4"*4", 6"*6", 9"*9", 12"*12", cusotmized |

| Clean class | 100/1000 |

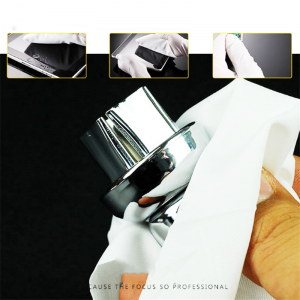

| Cutting Style | Laser/Cold/Hot/Ultrasonic |

| Package | Depends on the size or Customized |

| Application Field | Electronics industry, Cleanroom, Optical devices, Optical fiber manufacture, Printing, SMT, Precision equipment, Food & pharmaceutical, Mechanical processing, etc. |

| OEM/ODM | Available |

| Features | 1. Superb softness;

2. Low dust loading; 3. Cleanroom laundered and packaged; 4. High liquid absorption rate;Low ions and NVR. |

1, They are comprised of 100% continuous filament polyester in a straight-knit pattern. And we could provide 4 kinds of sealed edges to prevents the release of fibers and particles.

-Laser seal edge

-Heat seal transparent seal edge

-Ultrasonic narrow edge

-Ultrasonic wide edge

2, Highly absorbent with extremely low levels of particulate and extractable counts.

3, Laundered and packaged in a cleanroom

4, Tested and manufactured in ISO compliant facilities

Product features

-Fully sealed border to prevent fiber release

-Resist abrasion under rigorous use

-High sportive capacity decreases wipes required

-Assure cleanliness with ultralow levels of ions and lints

-Economical, good abrasion resistance

1. 18MΩ pure water laundered, clean room class10, 000-10 packing.

2. Soft and no harmful to wiped surface.

3. High efficient absorbency

4. Ultro-low particle and dust generation.Remark: Can be medical used after sterilization or be added with alcohol, IPA solutions and so on.

Product Description

|

Specs |

4*4 inch |

6*6 inch |

9*9 inch |

|

Packing |

600 sheets/bag,10 bags/CTN |

150 sheets/bag,24 bags/CTN |

150 sheets/bag,10 bags/CTN |

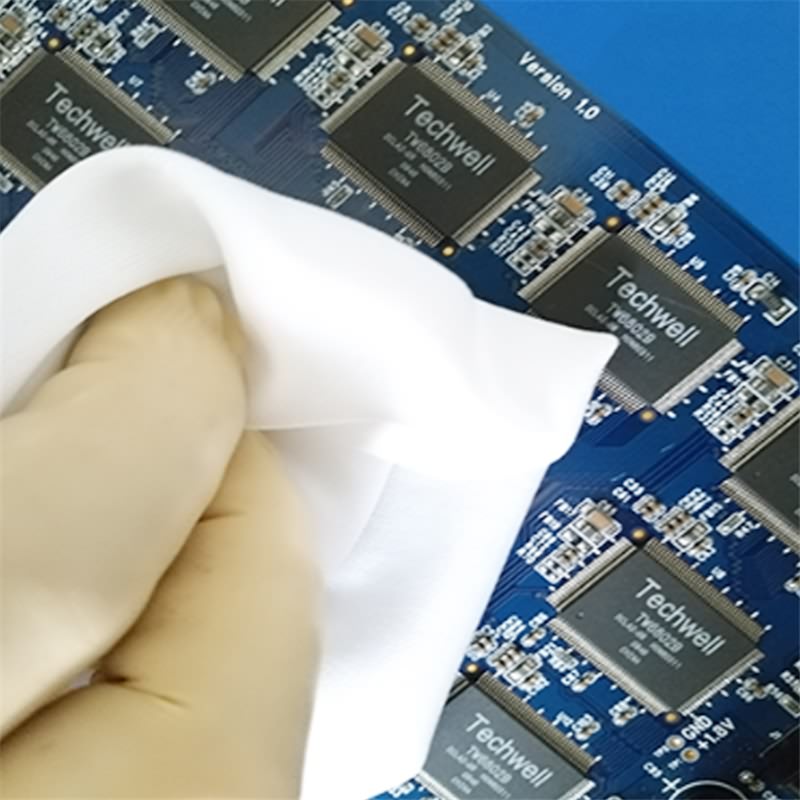

Applications:

The wipes are ideal for wiping the interior of process tools and other equipment as well as for general wiping in environments where contamination control is necessary. Widely used in class 100 cleanroom, electronics, pharmaceutical, chemical industry, semiconductor production line, chips and microprocessor etc

1. It is designed for critical processing applications where the high level of contamination control is required.

2.It is widely used for cleaning in industry of Clean room, Semi-conductor, TFT, LCD, micro-electronics, integrated

circuit,precision instrument, PCB, SMT, medical, lab and aviation etc