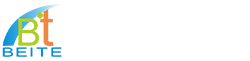

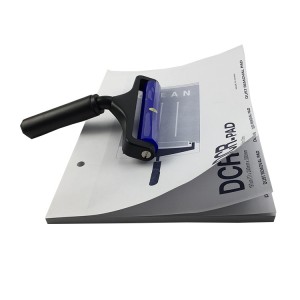

Wood pulp polyester SMT stencil wipe roll

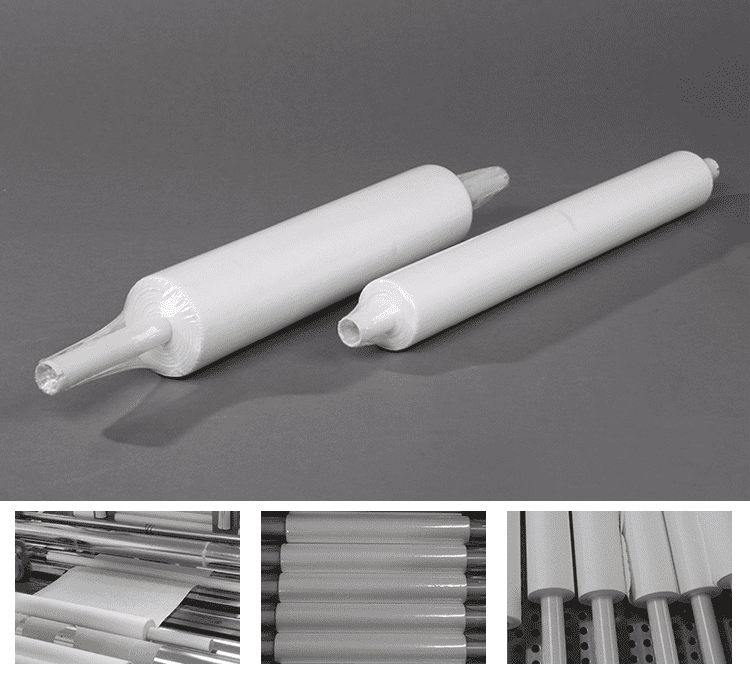

Features:

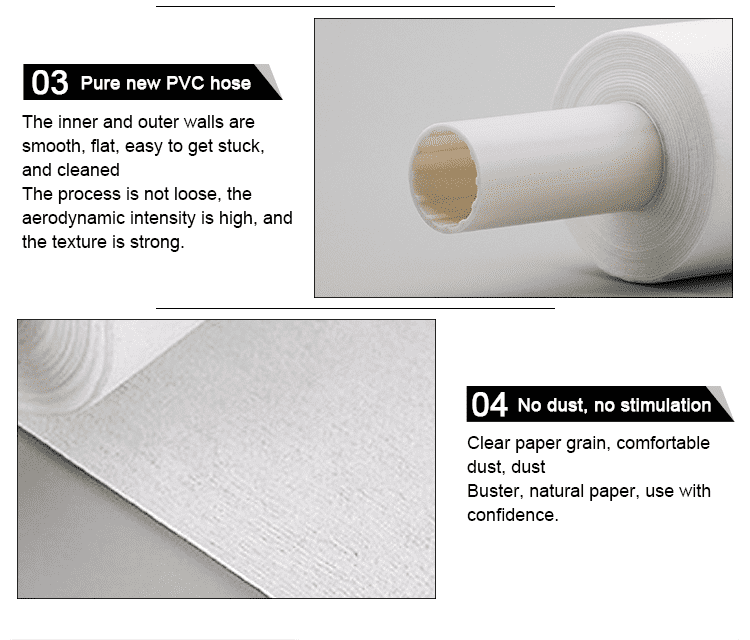

Because of the production in the cleanroom, the inclusion of impurities in the wiping paper is avoided, and the occurrence of printing defects caused by impurities entrained in the wiping of the steel mesh in the printing process can be reduced. The material is soft, which does not produce any scratches or damage the surface of the object. Tough and durable, with high-efficiency water and oil absorption, soft, dust-free and antistatic properties.

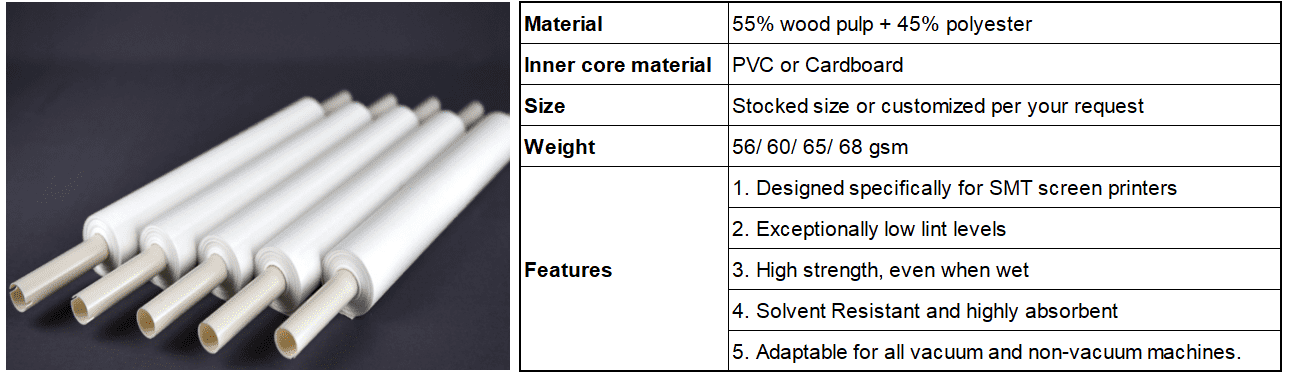

Product display

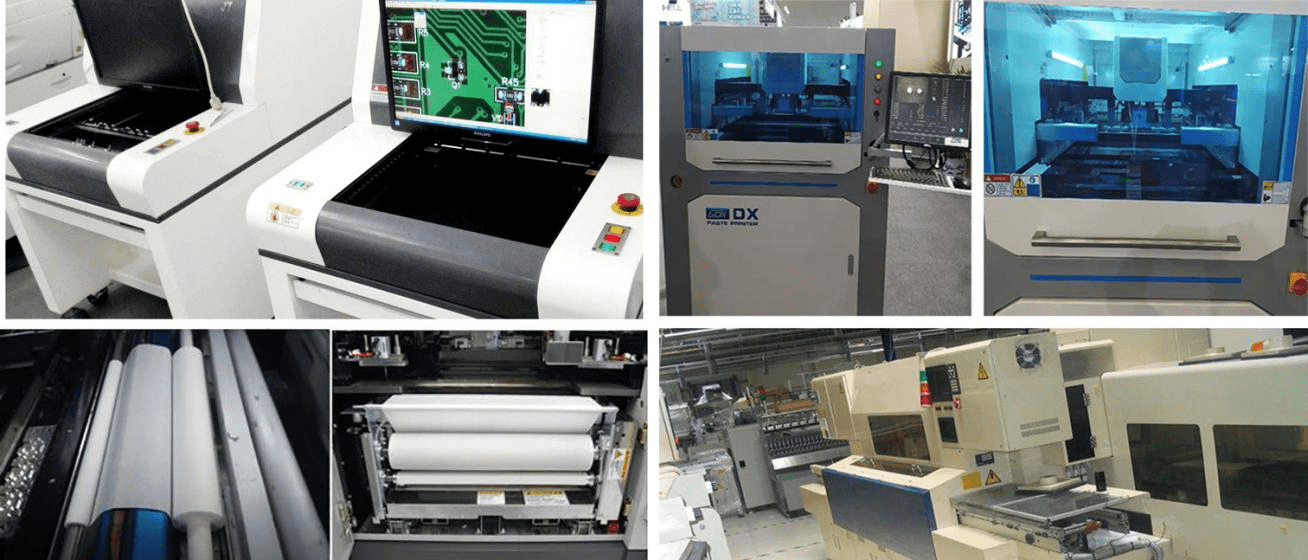

Scope of application:

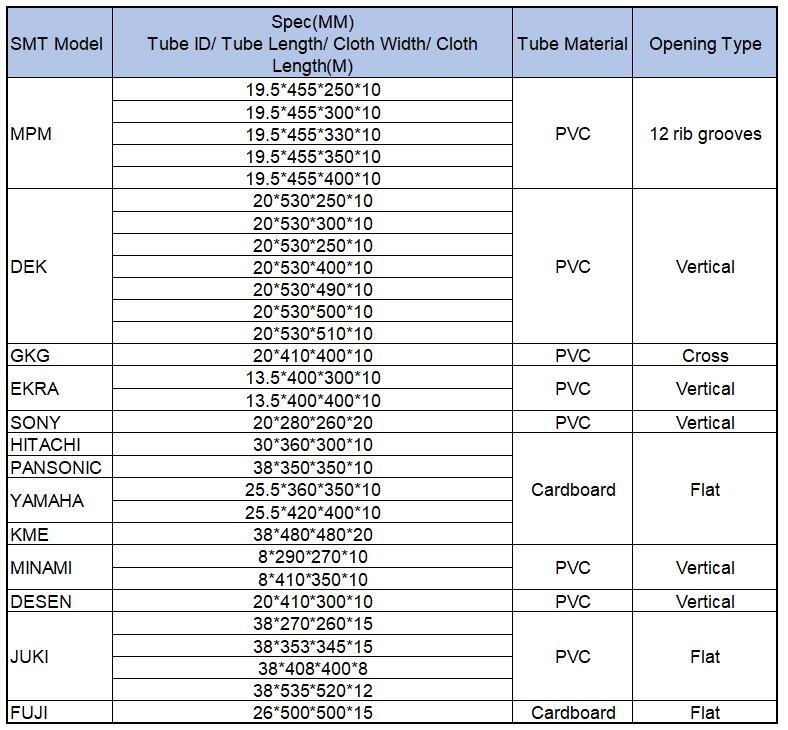

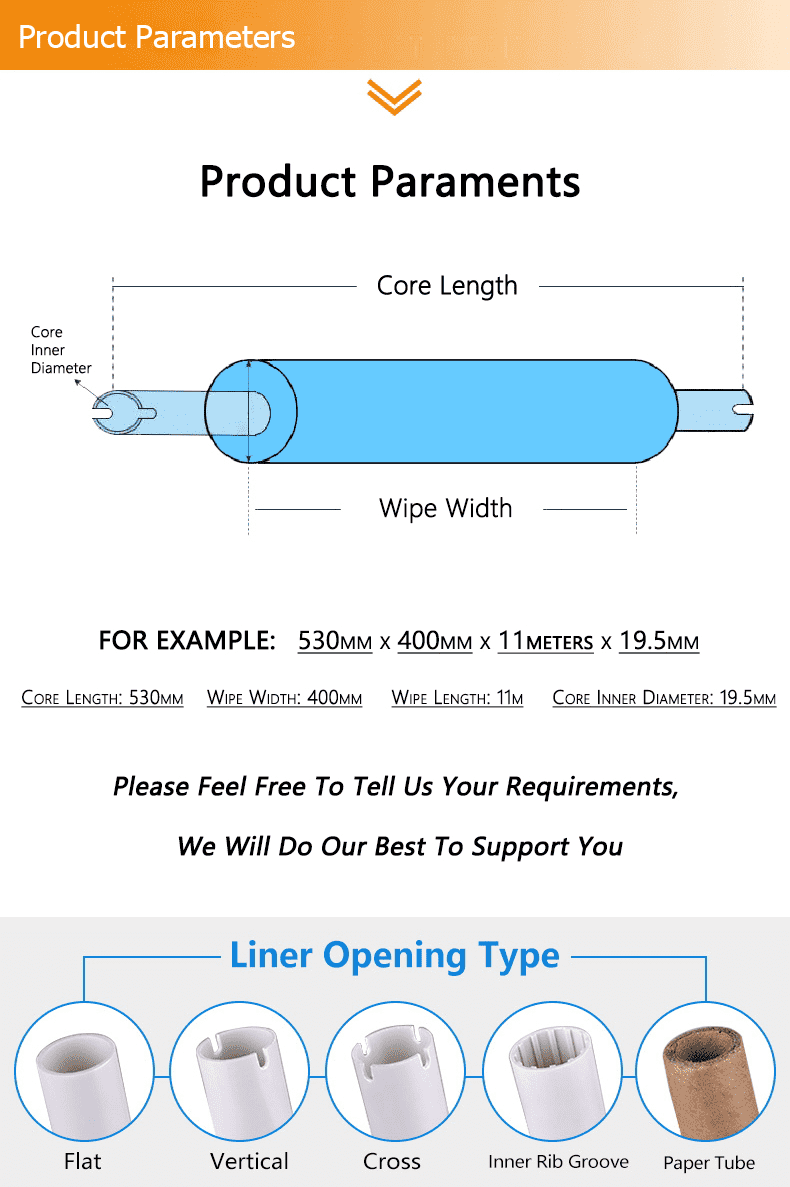

It can be used for all automatic printing machines such as MPM, DEK, KME, Yamaha minani juki ekra panasert fujisanyo, etc.

Write your message here and send it to us